Why Do Some KI Products Use TFM1600 Instead of PTFE for Valve Sealing

We believe in Simple & Creative

Why Do Some KI Products Use TFM1600 Instead of PTFE for Valve Sealing

Why Do Some KI Products Use TFM1600 Instead of PTFE for Valve Sealing

February 25, 2025

February 25, 2025

Why Do Some KI Products Use TFM1600 Instead of PTFE for Valve Sealing?

Key Advantages of TFM1600

✨Introduction

TFM1600, a second-generation modified PTFE developed by Dyneon GmbH, represents a significant advancement in fluoropolymer technology. This high-performance engineering plastic builds upon traditional PTFE's foundation while offering enhanced characteristics.

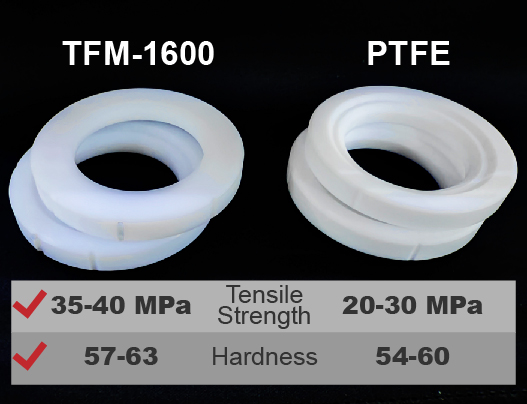

✨Physical & Mechanical Properties

|

Property |

TFM1600 |

PTFE |

|

Density |

2.16 - 2.19 g/cm³ |

2.14 - 2.20 g/cm³ |

|

Tensile Strength |

35 - 40 MPa |

20 - 30 MPa |

|

Hardness (Shore D) |

57 - 63 |

54 - 60 |

|

Surface Roughness |

< 0.05 μm |

0.1 - 0.2 μm |

✨Performance Advantages of TFM1600

1 Higher pressure handling capacity

2 Superior tensile strength across temperature range

3 Better thermal stability

4 Enhanced dimensional stability

5 Extended service life

6 Reduced maintenance requirements

7 Improved process reliability

8 Better cost efficiency

✨Industrial Applications

1 Chemical Processing: Reactor seals, pipeline linings and storage systems

2 Pharmaceutical: Sterile equipment, pure water systems and production line seals

3 Semiconductor: Wafer processing, ultra-pure systems and gas distribution

✨Conclusion

TFM1600 demonstrates superior performance characteristics compared to standard PTFE, particularly in demanding applications requiring:

1 High pressure resistance

2 Temperature stability

3 Mechanical strength

4 Chemical resistance

This makes it the preferred choice for critical industrial applications where standard PTFE might reach its performance limits.