A New Factory Build Up in Vietnam !

We believe in Simple & Creative

A New Factory Build Up in Vietnam !

A New Factory Build Up in Vietnam !

October 30, 2019

October 30, 2019

|

● Vertical integrated production system to deliver consistent quality. |

|

|

Plant Outline

● Established : Year 2019● Land Space : 764,237 ft²( 71,000 m²) ● Floor Space : Casting Shop: 365,973 ft² (34,000 m²) Machining Shop: 172,222 ft² (16,000 m²) ● Employee : 380 ● Capacity : 300 metric tons monthly (planned) ● Activities : Manufacturing of fittings and mechanical parts |

|

|

|

● Large capacity with capability for expansion to service your growing demand. |

|

Casting Shop

Two-story building with total floor space of 365,973 ft² (34,000 m²)

Estimated completion: End of June, 2019 |

|

|

|

|

Machining Shop

Two-story building with total floor space of 172,222 ft² (16,000 m²)

Estimated completion: End of July , 2019 |

|

|

|

|

|

||

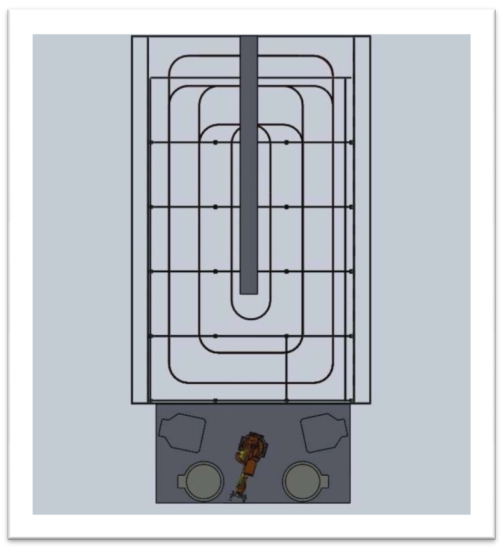

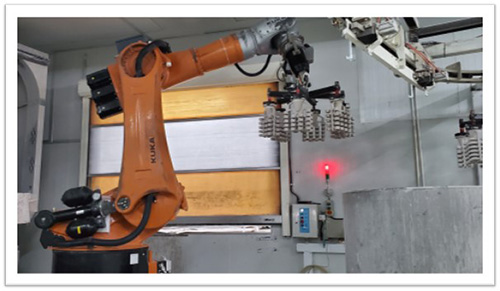

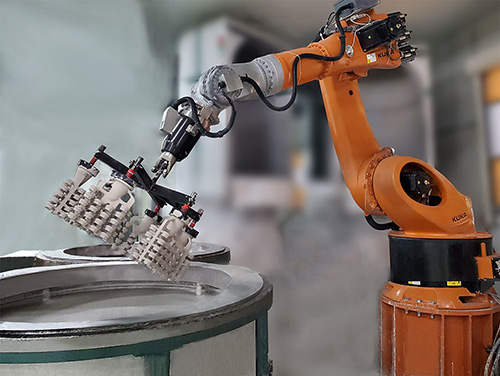

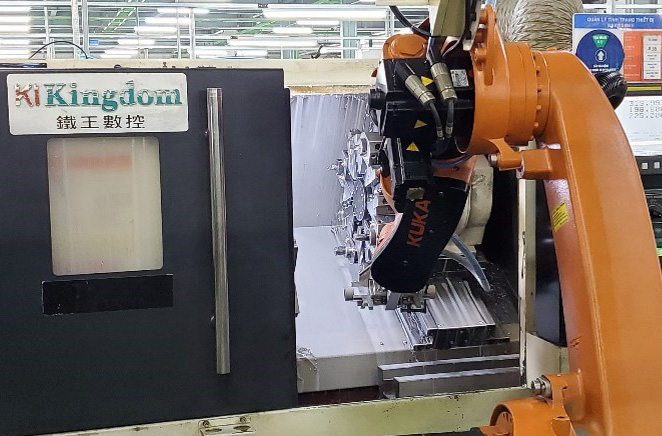

| ● Automatic production equipment to provide efficient and stable process. Vietnam factory is equipped with the advanced automatic production system such as robotic arms for shelling making and machining process to provide high efficiency and stable quality. |

||

| Main Production Equipment | ||

| Advantages | Equipments & Facilities | Q'ty |

|---|---|---|

| ● Automatic and semi-automated wax injection & dewaxing equipments enhance production efficiency for wax castings. |

Automatic Wax Injection Machine | 6 |

| Semi-Automated Dual Station Wax Injection Machine | 8 | |

| Semi-Automated Disc Type Wax Injection Machine | 2 | |

| Semi-Automated Dewaxing tank | 2 | |

| ● Stable Shell Mold Production System | Automation Solution for Shelling Process (KUKA) | 4 |

| ● Stable & Efficient Drying System in Shell Molds | Constant temperature and humidity Controling Room | 4 |

| ● Low Energy Consumption Furnaces | High Efficiency 300KW Medium Frequency Melting | 4 |

| Semi-Automated Pre-heat Furnace For Shell Mold | 4 | |

| ● Safey & Quality Improved Heat Treatment Process | Nitrogen-Based Atmosphere of Heat Treatment Furnace | 4 |

| ● Automatic & semi-automated equipments enhance production efficiency and reduce workload in workshop. |

Robotic Arm for CNC Machining process | 4 |

| Gantry Robot for CNC Machining process | 4 | |

| ● High Capacity Machining Facilities | CNC Lathe | 80 |

| Semi-Automated Tapping Machine | 20 | |

| Automatic Tapping Machine | 6 |

|

|

|

|

|

|

|

|

|

|

|

|

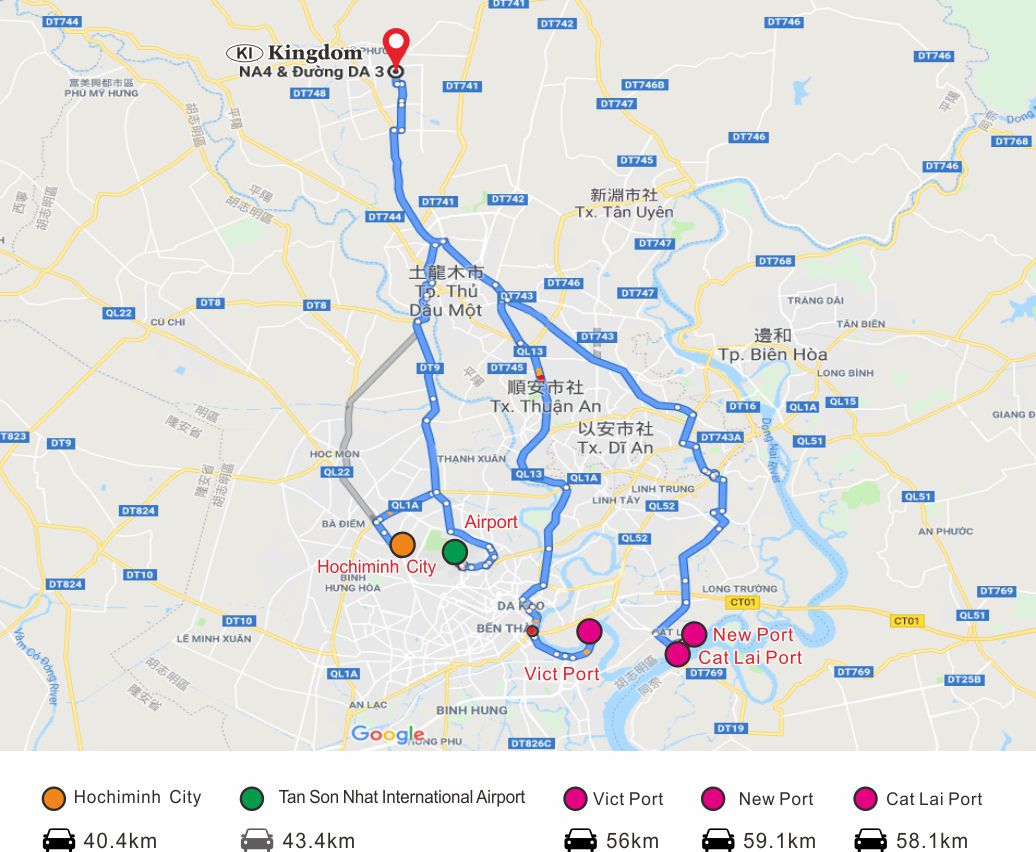

| ● Excellent location for convenient transportation. Vietnam factory is close to major airport and seaports in Hochiminh |

|

|

|

|