Why Do Some KI Products Use TFM1600 Instead of PTFE for Valve Sealing

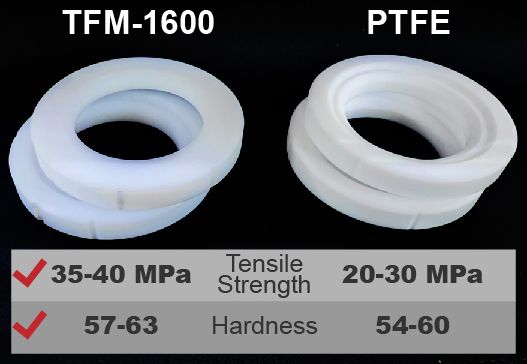

Introduction: TFM1600, a second-generation modified PTFE developed by Dyneon GmbH, represents a significant advancement in fluoropolymer technology. This high-performance engineering plastic builds upon traditional PTFE's foundation while offering enhanced characteristics.

Why Do Some KI Products Use TFM1600 Instead of PTFE for Valve Sealing - KI Kingdom

KI Kingdom is a Taiwan valve manufacturer and industrial valve supplier helping global plants stabilize production with reliable industrial valves and flow control solutions for oil and gas, petrochemical, power generation and water treatment projects.

Founded in 1973 in Kaohsiung, Taiwan, KI Kingdom has expanded with manufacturing facilities in China and Vietnam, integrating R&D, machining, assembly, testing and service under one roof. Our product range includes metal seated ball valves, gate, globe, check and butterfly valves, pipe fittings, quick couplings and pneumatic and electric actuators.

Through strict material control, process inspection and performance testing, KI Kingdom delivers industrial valves that maintain tight sealing and long service life under high pressure, high temperature and corrosive media, supporting engineers and buyers in demanding flow control applications.